This is our journey of an epic father/daughter ‘56 Chevy pickup build. My whole life has been around old trucks, car shows and watching my dad restore his ’72 Ford F250. In 2011, my dad and I set out to find a project truck. It wasn’t until late 2012 that I saw an ad in our local newspaper for a 1956 Chevy Apache. I asked my Dad to check it out on his way up island. He called me back and said I had better drop what I’m doing and come have a look right away. I drove up that afternoon; my Dad and I test-drove it and purchased it that day. I have always had a real passion for old iron, so when I saw this truck I knew it was the perfect project truck for my Dad and I.

Small world that it is, it was some good friends of ours that were selling this truck. They had brought it up from Sacramento two months earlier, and the truck had never seen rain until it arrived here on Vancouver Island.

I drove it for the first two years with drum brakes and armstrong steering. The truck at the time was stock except for the 350 SBC and the T350 transmission. During the first year, my Dad and I replaced the painted grille with a chrome one, replaced the glass in the doors with a single glass, eliminating the no-draft and installed stock mirrors. We read every truck/hot rod magazine we could find and hit all the rod shows before we came up with a combination for wheels /tires and a target ride height. We went for Boss series 18 X 8 wheels up front and 20 X 10s on the rear, wrapped in Bridgestone 225/45s on the front and 315/35s on the rear.

Hot rodding friends, suppliers, Instagram friends and our local Torque Masters Car Club were all a great help with advice and encouragement to help keep the project on track. Through 2012 and 2013, we started picking up bits and pieces for the project and preparing for the first stage of the build.

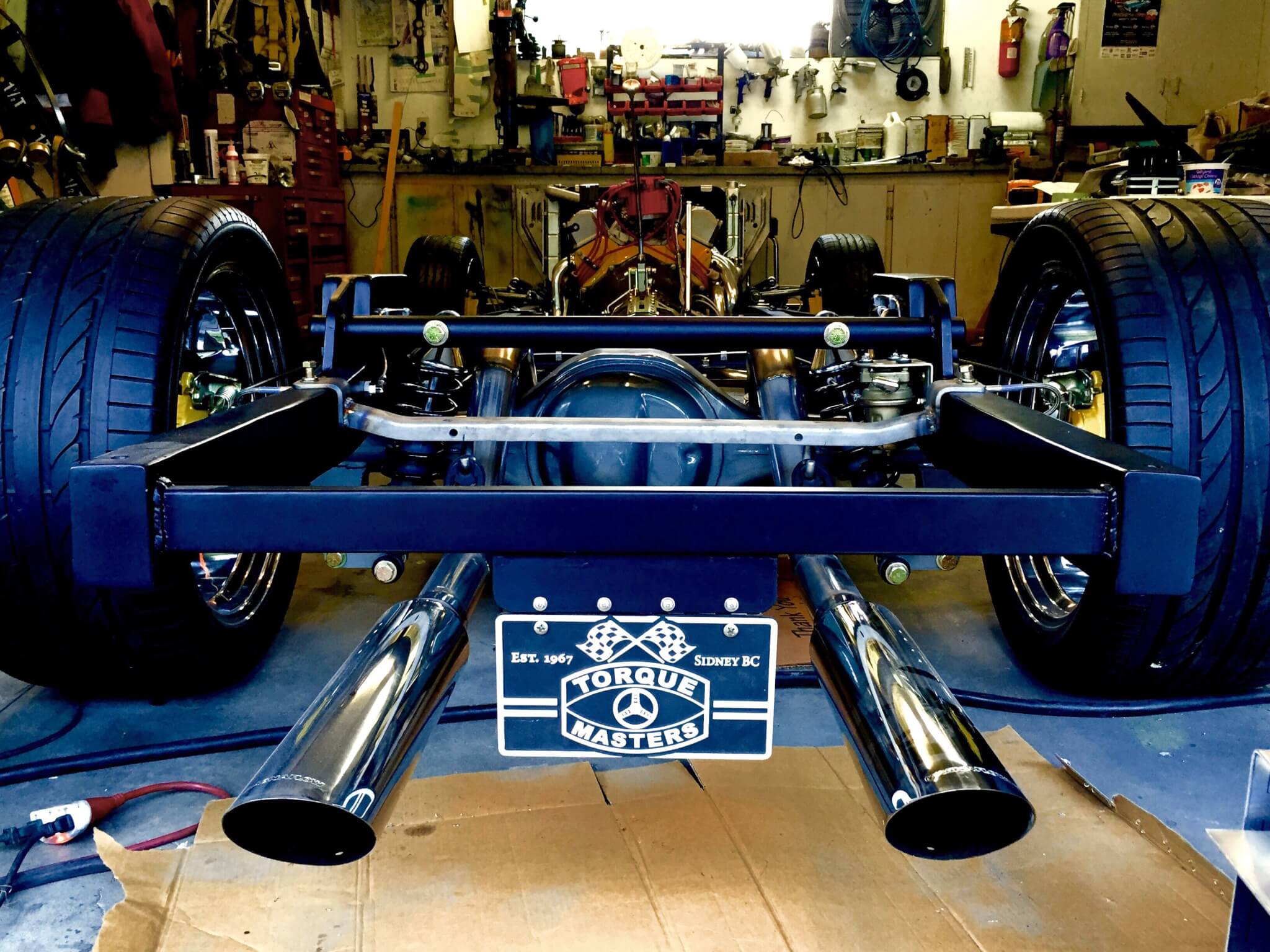

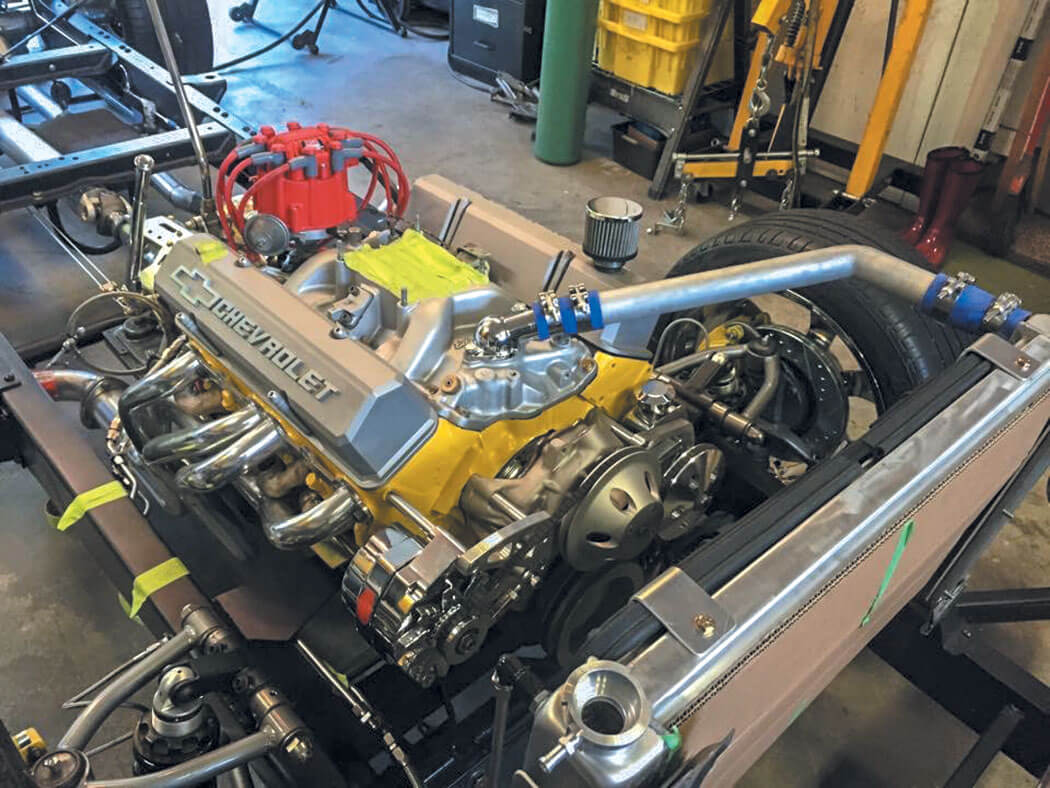

During the spring of 2014, my dad and I completely disassembled the truck to a bare frame. We cleaned, sandblasted, boxed, filled all the unneeded holes, fabricated a custom C-notch, installed wiring looms within the frame rails and painted it. We installed TCI’s latest generation IFS Mustang II frontend and a narrowed Ford 9″ rearend with a TCI 4 Link. We installed adjustable coilovers front and rear. We set the engine low with a 4” clearance and pushed it back 6” to get a 55/45 front-to-rear weight ratio. I plan to get into auto cross/pylon racing at some point with the truck.

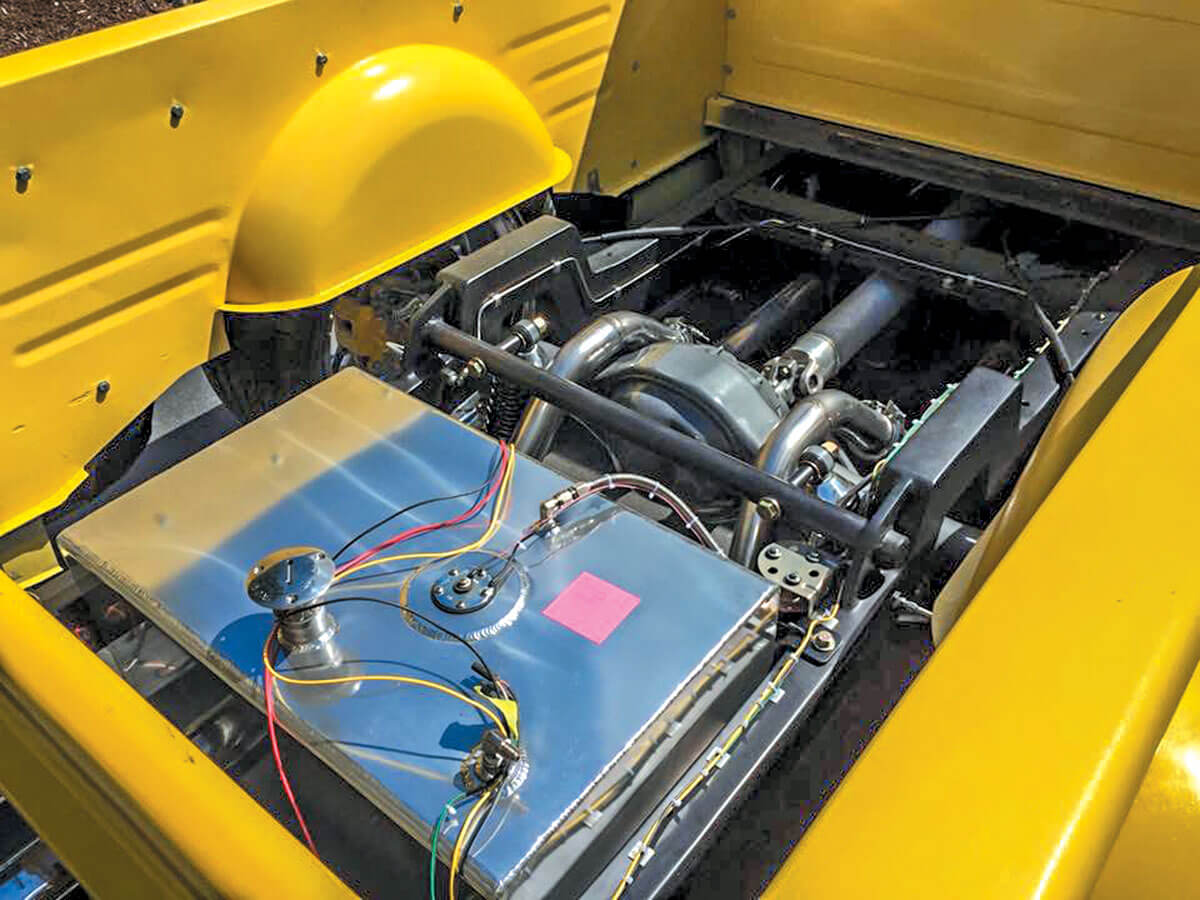

The 350 was an early 1970s block with 4 bolt mains and 202/194 heads that ran strong and had been freshened up, so we stuck with it to keep the budget under control. We detailed the block with high build primer and Valspar top coat to match the exterior paint, replaced the timing chain and gear set, added a high volume oil pump and 9 quart Moroso oil pan, Edelbrock manifold, a 1405 series Edelbrock carb, added a chrome alternator and Chevy low pressure ham can power steering pump, all this hung on March brackets nice and low; we added die cast rocker covers, MSD ignition, Doug’s ceramic long tube headers with electric cutouts and topped this off with a 1956 Cadillac air cleaner. We ran 2-1/2″ SS exhaust pipes through 40 series Flowmaster mufflers to 4” X 22” SS tips at the rear. Hooked on to the 350 is now a completely done 700R4 with a Lokar shifter. To fit the 315 R 20s in the back, we had to tub the box 4″ using Dan Carpenter tubs. Everything under the hood is kept cool with a large cross flow aluminum rad with dual fans triggered with a Ron Francis controller.

With the help of club friends, we fabricated an 18 gallon baffled aluminum fuel tank for the rear, the fuel is pushed to the carb through a Carter electric pump and all SS plumbing with AN fittings.

To rein all this in, we installed a CPP master cylinder and 11.5 GM discs front and back, all plumbed in SS with AN fittings, residual valves, a rear adjusting valve and a line lock.

We still have a ways to go on the “rodsteration” project with more bodywork/paint, box bed and the interior to complete. However, we were on the road to get any bugs sorted out for the July 1st Canada Day parade last summer and that was a great feeling. This project became my whole life. I spent countless hours working on this truck with my dad, learning skills such as welding, grinding (which I hate), fitting, wiring, polishing (three days just on the fuel tank) and painting during this build. It has been an amazing journey getting here. Thanks to LMC for shipping parts direct to Canada. “You can’t buy happiness, but you can buy a truck and that is pretty much the same thing.” LMC, thank you! You guys rock!